This guide offers examples of basic supply chains for producing constructed materials in Orebond.

Orebound: Supply Chain Guide

In this guide, you’ll find multiple examples of supply chains for efficient production in Orebond.

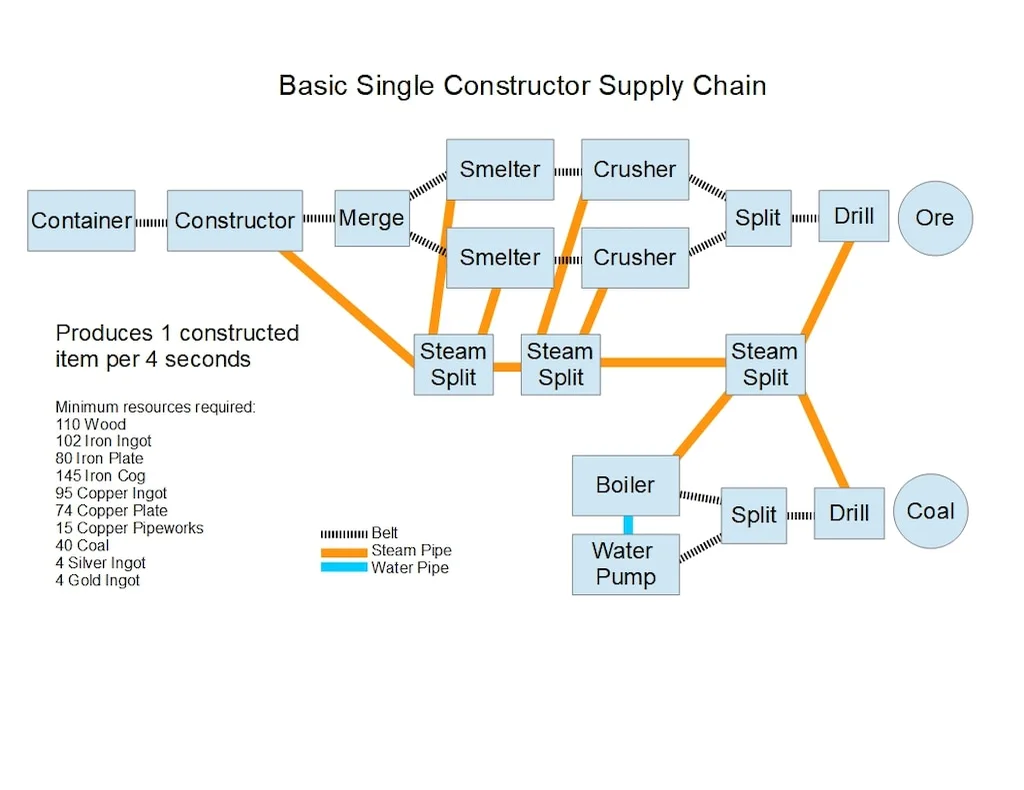

Single Constructor Supply Chain

This diagram outlines a simple supply chain designed to keep a single constructor running at full efficiency (producing 1 item every 4 seconds). While the setup uses a belted water pump and boiler, it can also function with manually fueled machines—though this would slightly alter the minimum resource requirements. By adding an extra splitter, merger, and container, the setup can be adjusted to produce ore ingots, though this will reduce the production speed. (Refer to the Double Constructor example below.)

The system consumes only 90 out of the 100 steam units generated by the boiler, leaving enough capacity to power an additional drill for nearby raw materials that don’t require further processing, such as wood or stone.

This supply chain will require the following (minimum) machines:

- 2 Drills

- 3 Belt Split / Merge

- 2 Crushers

- 2 Smelters

- 1 Constructor

- 1 Auto Water Pump

- 1 Belt Boiler

- 3 Steam Splitters

- 12 Belts

- 1 Water Pipe

- 10 Steam Pipes

- 1 Belted Storage

This will require the following materials:

- 110 Wood

- 102 Iron Ingot

- 80 Iron Plate

- 145 Iron Cog

- 95 Copper Ingot

- 74 Copper Plate

- 15 Copper Pipeworks

- 40 Coal

- 4 Silver Ingot

- 4 Gold Ingot

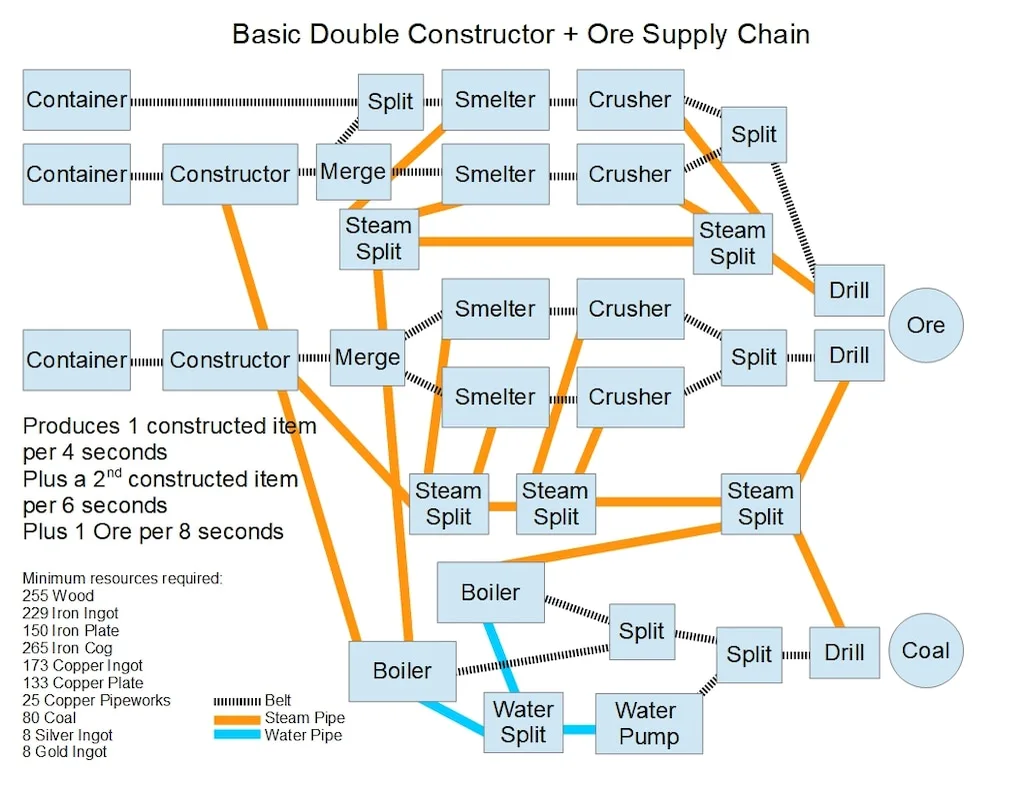

Double Constructor + Ingot Supply Chain

This diagram illustrates a supply chain capable of producing two constructed items alongside ore ingots. The first item is crafted every 4 seconds, the second every 6 seconds, and one ore ingot every 8 seconds. Once the ore ingot container reaches capacity, the second item will also be produced every 4 seconds.

This setup is ideal for resources like Iron and Copper, enabling the production of Iron Cogs, Iron Plates, and Iron Ingots efficiently. While the diagram assumes a belted water pump and boiler, it can also operate with manually fueled machines, though this would slightly alter the required materials.

The system utilizes only 170 out of the 200 steam units provided by the boilers, leaving additional capacity to power more drills for nearby raw materials that don’t need processing, such as wood or stone.

This supply chain requires the following (minimum)machines:

- 3 Drills

- 7 Belt Split / Merger

- 4 Crusher

- 4 Smelter

- 2 Constructor

- 1 Auto water Pump

- 2 Belt Boilers

- 5 Steam Splitters

- 1 Water Splitter

- 26 Belts

- 3 Water Pipes

- 18 Steam Pipes

- 3 Belted Storage

Minimum resources required:

- 255 Wood

- 229 Iron Ingot

- 150 Iron Plate

- 265 Iron Cog

- 173 Copper Ingot

- 133 Copper Plate

- 25 Copper Pipeworks

- 80 Coal

- 8 Silver Ingot

- 8 Gold Ingot